Explosion proof led light fixtures: energy storage industry safety lighting program

1. Energy storage industry lighting special challenges and the core value of LED explosion-proof lights

In the context of the rapid development of the energy storage industry, lithium battery storage power stations, battery storage pods and other facilities for the safety of lighting put forward stringent requirements.

Such environments exist flammable gases, dust accumulation and other explosion risks, traditional lighting equipment has been unable to meet the demand for intrinsic safety.

At this time, the use of approved ATEX / IECEx certified Explosion proof led light fixtures, into the protection of facilities to ensure the safe operation of the fundamental initiatives.

Energy storage places three major lighting pain points

Explosive environmental hazards: lithium energy storage pods in the charging and discharging process probably release hydrogen and other flammable gases

Severe environmental adaptation needs: -40 ℃ ~ +60 ℃ extreme temperature fluctuations test the reliability of equipment

Operation and maintenance cost control pressure: traditional explosion-proof lamps and lanterns with high energy consumption and short life increase the burden of operation

2. LED explosion-proof light technology advantages of analysis

2.1 Upgrade safety and protection performance

Professional design Explosion proof led light fixtures using die-cast aluminum shell and tempered glass shield, approved explosion-proof [Ex d] or increased safety [Ex e] explosion-proof structure, effectively curbing the risk of explosion caused by sparks.

It meets IP66/IP68 protection level design, which ensures stable work in the humid and salt spray environment unique to energy storage containers.

2.2 Revolutionary breakthrough in energy efficiency performance

Compared with traditional explosion-proof metal halide lamps, Explosion proof led light fixtures can be implemented:

Reduce energy consumption by more than 60% [150W LED instead of 400W traditional lamps and lanterns] luminous efficacy to 130lm / W above 50,000 hours of ultra-long service life [80% reduction in maintenance frequency].

2.3 Intelligent control integration potential

A new generation of Explosion proof led light fixtures with DALI dimming system, can be linked with the BMS system of the energy storage station, the implementation:

According to the ambient illumination automatically adjust the brightness motion detection intelligent start and stop energy consumption data real-time monitoring.

3. Typical application scenarios in the energy storage industry in-depth analysis

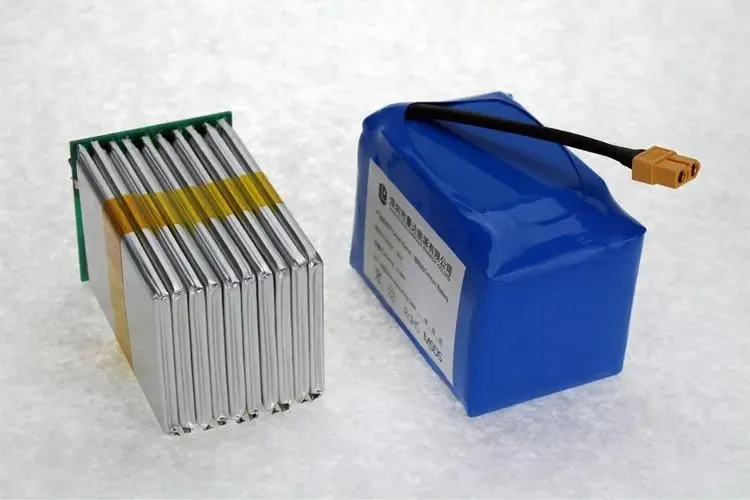

3.1 Lithium battery energy storage cabin lighting program

In the closed battery storage container, LED explosion-proof lights need to meet:

Explosion-proof grade: Ex IIB T4 and above color temperature selection: 5000K natural white light [accurately identify the state of the equipment] Installation method: wall mounted using anti-vibration bracket / lifting design

3.2 Explosion-proof lighting for energy storage distribution room

Recommended configuration for the arc risk distribution cabinet area:

Explosion proof led light fixtures with emergency function [180 minutes backup power] anti-electromagnetic interference design [in accordance with EN 61000-4 guidelines] wide-angle light distribution [120 ° irradiation angle covering the equipment area].

3.3 Lighting layout for outdoor energy storage power stations

For the outdoor area of large-scale energy storage power station, it is advocated to adopt:

Integrated photovoltaic panels off-grid Explosion proof led light fixtures with 10KV lightning protection care pole lamps and lanterns intelligent sensor control [car / people into the automatic start].

4. Professional selection guide: six dimensions to choose the appropriate Explosion proof led light fixtures

4.1 Explosion-proof certification match: confirm the place Zone classification [0/1/2 zone] to choose the corresponding certification

4.2 Optical system improvement: according to the equipment maintenance channel width to choose the light distribution curve [wide beam / narrow beam].

4.3 Thermal management design: Select aluminum alloy housing with heat dissipation fins [surface temperature <80℃].

4.4 Seismic performance verification: approve IEC60068-2-6 vibration test [frequency range 5-150Hz].

4.5 Convenience of maintenance: Quick-open structure design [bulb replacement within 3 minutes].

4.6 Intelligent pre-maintenance: equipped with LED status monitoring chip [early warning of light failure].

5. Industry foresight: Explosion proof led light fixtures technology development momentum

Digital twin integration: approval of the built-in sensors to implement visual monitoring of the health status of the lamps and lanterns

New energy integration: the development of wind and solar complementary power supply off-grid explosion-proof lighting

System material innovation: graphene heat dissipation coating application to reduce the weight of the lamps and lanterns by 40%.

Spectrum customization: Developing special wavelength explosion-proof lighting for lithium battery inspection needs [e.g. infrared detection auxiliary lighting].

6. Successful cases: a 200MWh energy storage power station lighting renovation project

Approved to replace 327 sets of Explosion proof led light fixtures, the implementation:

Annual electricity cost saving: $58,200 [payback period <2 years].

Failure rate reduction: 92% [compared to the original high-pressure sodium lamp system].

Improvement of illumination uniformity: 0.82→0.91 [EN 12464-1 guideline].

7. Conclusion

As the core equipment for safe lighting in the energy storage industry, Explosion proof led light fixtures are being approved for technological innovation to reshape the industry norms. Choose to approve the IECEx/ATEX dual certification of quality products, not only to meet the regulatory requirements, but also for energy storage facilities to build intrinsically safe line of defense. Contact our team of explosion-proof lighting experts for customized lighting solutions.